133

133

Series 90 Controls

When temperature control began to transition from pneumatic to electric a problem of how to modulate the signal arose. Radios had been around for a long time with volume controls. Electric lights had been using dimmer rheostats for some time as well. Utilizing the principle that varying resistance would result in varying current flow gave rise to what we now call Series 90 controls.

Series 90 comes from Honeywell’s nomenclature system. It denotes a 135-ohm potentiometer circuit. Other manufacturers utilize Five –hundred and 1000 ohm circuits. The higher ohm ranges give us control that is more precise but they allow overshooting and over compensating or a condition called hysteresis. The Latin root for that word is the same a hysteria. We don’t want hysterical temperature controls. Series 90 is slower to react so the responses are smoother.

We see from a rheostat that more resistance to the flow of current results in a dimmer light. Less resistance to the flow of current allows more reaction by the magnet in the back of a speaker and louder output. A series 90 circuit has a rheostat or in more universal terms a potentiometer at both ends. They will always try to reach a point of balance. If a temperature control is out of balance the connected actuator moves until it has balanced the circuit.

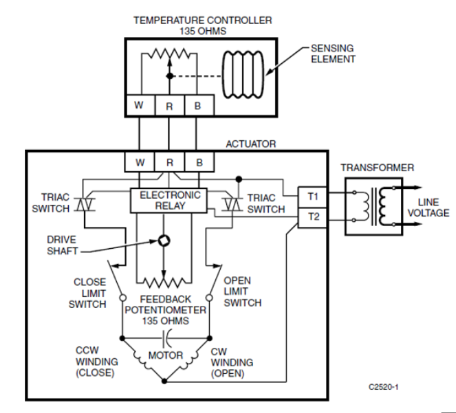

In this illustration, we see that the sensing element mechanically moves the wiper designated by R. Voltage from the transformer flows through R and out the path of least resistance. The corresponding triacs energize a winding to move the motor. The feedback potentiometer signals the balance relay of the desired change of position and the windings de-energize. A typical sensing element connected to this system would expand as it got warm and contract as it cooled. The wiper moves toward W on temperature rise and toward B on temperature fall.

Testing a series 90 controller involves an ohmmeter to read from R to W, R to B, and W to B. W to B is the full potentiometer so it should read 135 ohms. As high as 150 is still considered normal. R to W, and R to B should add up to 135 ohms. Moving the wiper should change the reading but they will still add up to 135 ohms. Removing all the resistance with a jumper from R to B would drive the above motor full

Dallas Strong

Honeywell Series 90 Controls Overview

The Honeywell Series 90 control system was developed to address the challenge of modulating temperature control signals during the transition from pneumatic to electric systems. By utilizing variable resistance to regulate current flow, the Series 90 system efficiently controls temperature without the instability seen in higher-resistance circuits.

Key Features of Series 90 Controls

1. 135-Ohm Potentiometer Circuit

-

The "Series 90" designation refers to Honeywell's 135-ohm potentiometer circuit.

-

Competing systems may use 500 or 1000-ohm circuits, which offer finer control but may result in overshooting or unstable temperature swings (hysteresis).

-

Series 90’s slower response ensures smoother operation with less fluctuation.

2. How Series 90 Controls Work

-

A potentiometer is used at both ends of the circuit to balance the system.

-

When a temperature imbalance occurs, the connected actuator adjusts until the circuit returns to balance.

3. Control Process

-

The sensing element mechanically adjusts the wiper (designated R).

-

Voltage flows from the transformer through the wiper and follows the path of least resistance.

-

Triacs energize motor windings to adjust the actuator.

-

A feedback potentiometer signals the balance relay when the desired position is achieved, de-energizing the windings.

4. Temperature Response

-

As the sensing element expands (with rising temperature), the wiper moves toward the W terminal.

-

As the element contracts (with cooling), the wiper moves toward the B terminal.

Testing a Series 90 Controller

To test the circuit, follow these steps:

-

Use an ohmmeter to measure:

-

R to W, R to B, and W to B.

-

-

W to B should read 135 ohms (up to 150 ohms is acceptable).

-

R to W and R to B should always add up to 135 ohms.

-

Moving the wiper should change individual readings, but the combined total should remain 135 ohms.

-

Placing a jumper between R and B will drive the motor fully open or closed.

Final Notes

Understanding the fundamentals of the Series 90 system ensures accurate diagnostics and effective system adjustments. This reliable control method is widely used in HVAC systems for its stability and smooth operation.

For additional support, contact Johnstone Supply for expert guidance and system components.