97

97

Basic oil notes

🔧 Oil Heating Basics – Quick Reference Guide

🔥 Fuel Types & Heat Content

-

#1 Fuel Oil: ~135,000 BTU per gallon

-

#2 Fuel Oil: ~140,000 BTU per gallon

-

LP Gas (Propane): ~91,000 BTU per gallon

💡 Key System Specs & Tips

🔥 Oil Pump & Nozzle

-

Typical pump pressure: 140–150 PSI

-

Nozzles are rated at 100 PSI

-

Increasing pressure while using a de-rated nozzle improves atomization and ignition

-

🧯 Safety: Fuel Flash Point

-

#2 Fuel Oil Flash Point: 126°F

🌬 Draft & Airflow Settings

1. Overdraft (between heat exchanger and barometric damper):

-

Target: -0.04" WC

-

Set using the counterweight on the barometric damper

2. Overfire Draft (inside heat exchanger):

-

Target: -0.02" WC

-

Adjust using air bands on the burner

3. Excess Air:

-

Goal: 30% at steady state

4. Oxygen Level:

-

Maintain between 4%–7%

5. Stack Temperature:

-

Normal range: 325°F–600°F

🛠 Pump Diagnostics & Setup

✅ Pump Pressure Test:

-

Use a gauge to raise pressure to 160–170 PSI

-

Slowly reduce to 80 PSI

-

The needle should move smoothly (no skipping or stuttering) — indicates piston is working properly

-

⛔️ Oil Shutoff Test:

-

Pressure drop should be no more than 20% (e.g., from 100 PSI to no less than 80 PSI)

🔄 Single vs. Two-Pipe Systems

When installing a one-pipe system, connect the inlet line to the pump inlet.

The fuel pump may be installed with gravity feed or lift.

The maximum allowable lift for a single pipe installation is 8 ft.

| System Type | 1-Stage Pump Vacuum | 2-Stage Pump Vacuum |

|---|---|---|

| Single Pipe | 6” Hg | 6” Hg |

| Two Pipe | 12” Hg | 17” Hg |

When installing a two-pipe system, remove the 1/16” pipe bypass plug from plastic bag attached to fuel unit.

Remove 1/4” plug from return port. Insert and tighten the bypass plug. Attach return and inlet lines.

Note: Only install the bypass plug in the pump for two-pipe applications.

The return line should terminate approximately 3 to 4” above supply line inlet.

Failure to do this may introduce air into the system and could result in loss of prime.

Do NOT install valves in the return line.

-

Use 2-stage pumps for:

-

Long runs

-

Lifts over 6 feet vertically

-

🧮 Rule of Thumb (Vacuum Calculation):

-

1 ft vertical lift = 1" Hg vacuum

-

10 ft horizontal run = 1" Hg vacuum

Venting considerations:

Starting with minimum gph firing rate, the minimum size recommended is 6” flue pipe with 8” X 8” inside chimney, unless specified otherwise by the appliance manufacturer.

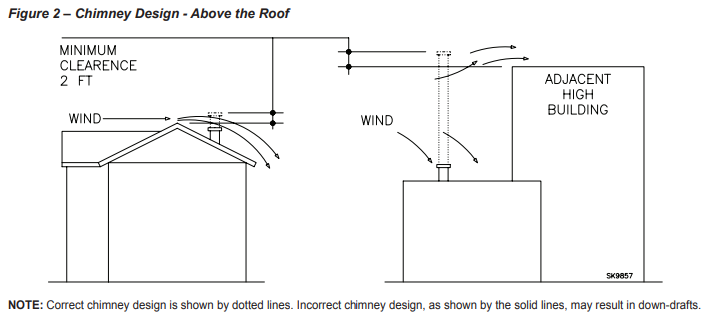

1. A chimney flue shall extend at least 3 feet above the highest point at which the chimney comes in contact with the roof, and not less than 2 feet above the highest roof surface or structure within 10 feet horizontally of the chimney.

Refer to Figure 2.

2. Any accumulation of soot or debris in chimney offsets should be removed

3. Any obstructions such as a protruding joint or a piece of broken tile wedged in the chimney should be removed

4. No other appliance connection should be made to the same flue pipe.

5. The flue pipe should have an upward pitch toward the chimney of at least 1/4” per foot of length. It should fit tightly and should not project into the chimney.

6. Any leakage between tiles, around clean-out doors, or around the vent pipe should be sealed.