103

103

Learning how to clock a gas meter can give you another tool in your belt to verify how a furnace is really running. It can also give you insight into system installation, namely gas piping. Below is an example of clocking a meter then we will give the mathematical formula to calculate this.

Example:

1. Turn off all gas appliances in the home.

2. Turn on the furnace. Ensure the furnace is operating at a 100% firing rate on 2 stage and modulating furnace product.

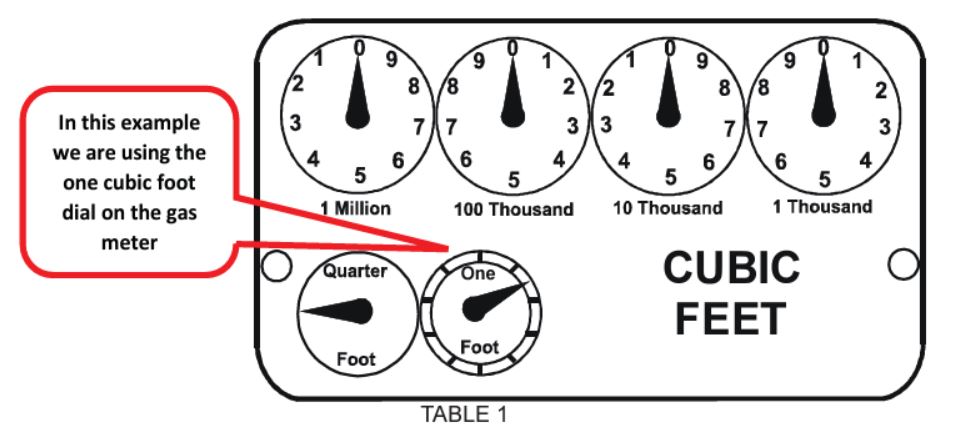

3. Once heating cycle is at a steady state (typically 15 minutes of operation), use a stopwatch to time how long it takes the smallest unit of measure dial on the gas meter to make a full revolution. In Table 1, one cubic foot is selected. The smallest unit of measure will vary depending on the gas meter.

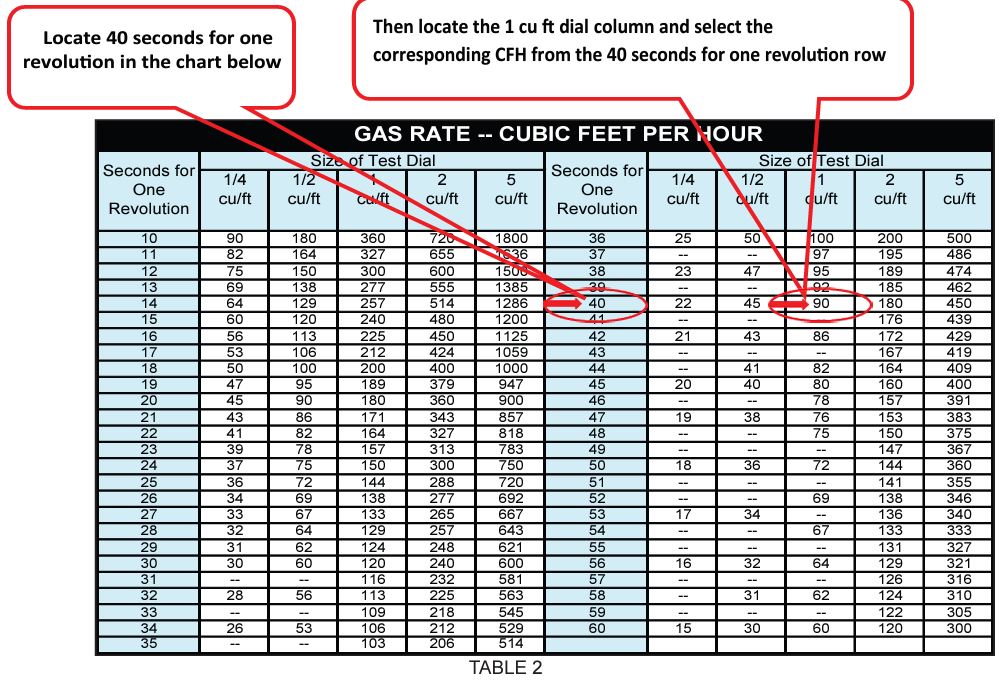

4. Using Table 2 below, find the number of seconds it took for the dial to make a full revolution. To the right of that number of seconds and below the Size of Test Dial (selected in step 3 and shown in Table 1) will be the Cubic Feet per Hour (CFH).

5. Use this formula to verify the Cubic Feet per Hour (CFH) input determined in step 4 is correct:

(3600 X Meter Dial Size)/ Time(seconds) = Cubic Feet Per Hour of Gas

6. Check with your local utility for actual BTU content (caloric value) of natural gas in the area (the average is 1025 BTU’s).

7. Use this formula to calculate the BTU/HR input (See BTU/HR Calculation Example): Cubic Feet per Hour (CFH) x BTU content of your natural gas = BTU/HR input

8. Should the figure you calculated not fall within five (5) percent of the nameplate rating of the unit, adjust the gas valve pressure regulator or resize orifices. To adjust the pressure regulator on the gas valve, turn downward (clockwise) to increase pressure and input, and upward (counterclockwise) to decrease pressure and input. A properly operating unit must have the BTU per hour input and CFM of air, within the limits shown to prevent short cycling of the equipment. As the external static pressure goes up, the temperature rise will also increase. Consult the proper tables for temperature rise limitation.